by Graham Fry | Apr 11, 2019 | Articles

Universal welding management software WeldEye is now available for managing the quality of robotic welding. By collecting data from the welding robot and synchronizing it with weld lists in the cloud service, WeldEye provides an effortless way of monitoring robotic...

by Graham Fry | Apr 11, 2019 | Articles

The Aristo Air PAPR (Powered Air Purifying Respirator) system combined with the Sentinel A50 Air helmet, offers heavy-duty protection from welding fume and dust when welding, gouging & grinding. The unit features the latest in PCB Board technology, allowing the...

by Graham Fry | Apr 11, 2019 | Articles

The goal of any Australian welding and fabrication company is to create quality products for their customers, while also managing costs and maintaining the desired levels of productivity and quality. Missed or defective welds can severely affect costs, productivity...

by Graham Fry | Mar 19, 2019 | Articles, Equipment, Welding

Leading international welding equipment manufacturer, Kemppi, has launched the new Kemppi X3 MIG family, an evolution of its popular HiArc MIG range. The X3 is a basic and cost-effective MIG alternative to Kemppi’s premium FastMig welding family, but with a high duty...

by Graham Fry | Mar 18, 2019 | Articles

Dynaweld, the welding supply experts, are delighted to announce the launch of the Bossweld TC16 hydrogen controlled, twin coated electrodes. The Bossweld TC16 hydrogen controlled, twin coated electrodes have been through a rigorous schedule of R&D and testing to...

by Graham Fry | Feb 18, 2019 | Articles

Performing gas tungsten arc welding (GTAW) on anodized aluminium is a bit like trying to poke a hole in a sheet of ice without disturbing the water underneath. In this case, the ice is the hard layer of oxide created by the anodisation process and the water is the...

by Graham Fry | Feb 18, 2019 | Articles

Leading international welding equipment manufacturer, Kemppi, has unveiled its new Kemppi X8 MIG Welder for extreme industrial welding – the ultimate choice for demanding welding. The X8 MIG Welder is a multi-process system for synergic and pulsed MIG/MAG welding, MMA...

by Graham Fry | Feb 15, 2019 | Articles

It is with great excitement that CIGWELD/ESAB announces the launch of the new Transmig 255i! These units will be available in early February with pre-orders being accepted NOW! The Transmig 255i is a compact self-contained single phase multi-process welding inverter,...

by Graham Fry | Feb 12, 2019 | Articles

The precipitation hardening (PH) stainless steels are a family of corrosion resistant alloys some of which can be heat treated to provide tensile strengths of 850MPa to 1700MPa and yield strengths of 520MPA to over 1500MPa – some three or four times that of...

by Graham Fry | Feb 11, 2019 | Articles

To confirm that a weld has been made to specification it is usually required to measure and often document the parameters that have been used. For arc welding the main parameters are as follows: Welding current Arc voltage Travel speed These parameters can be used to...

by Graham Fry | Jan 14, 2019 | Articles, Equipment

Take the guesswork out of welding with AUTO SET! The Cigweld Transmig 185 Ultra features an impressive AUTO SET function that allows the user to weld like a Pro with no previous welding experience necessary. Simply select the material type, thickness & consumable...

by Graham Fry | Jan 14, 2019 | Articles, Job Knowledge

Best practice in design is not simply a matter of deciding on the appropriate weld size or component thickness capable of carrying the service loads; there are many aspects of designing a welded component that need to be considered in addition to calculating...

by Graham Fry | Jan 14, 2019 | Articles, Job Knowledge

Low alloy steels are used extensively for high-temperature applications in power plants and the petrochemical industries but, while they have good weldability, they also present distinct challenges when they have been aged through service. This is because these...

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

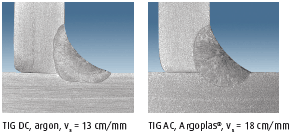

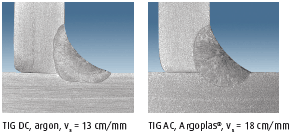

In TIG welding, the arc burns between the workpiece and a non-consumable tungsten electrode. To protect the electrode and molten pool from oxidation, both are shielded with an inert gas, generally argon. This welding process is suitable for all fusion-weldable metals....

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

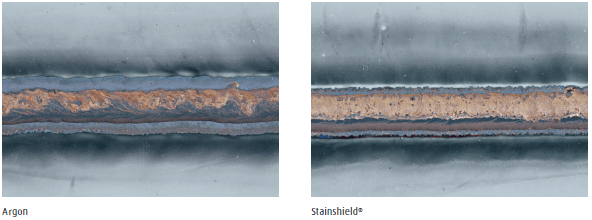

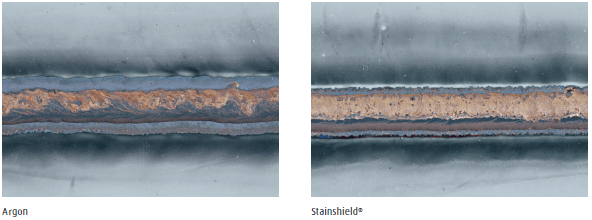

Gas metal arc brazing (GMA brazing) is an alternative method for joining primarily thin (t < 3.0mm) sheets that have been coated for corrosion protection. This method offers considerable advantages over GMA welding since an alloy metal with a lower melting point...

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

MIG welding of aluminium can be performed in the short, spray or pulsed arc. The advantages of the pulsed technique are that spatter formation is reduced and a wire electrode with the next largest diameter can be used. The larger diameter wire is easier to feed and,...

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

The shielding gases used for stainless steels differ from those used in GMA welding of unalloyed steels since they contain much less active gases, such as oxygen and carbon dioxide. This is necessary to prevent excessive oxidation of the passive layer responsible for...

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

The collective term ‘structural steel’ refers to unalloyed and low-alloyed steels, fine-grained structural steels that are suitable for welding mild steel. The choice of the most suitable shielding gas depends mainly on the type of filler metal, the material thickness...

by Graham Fry | Oct 17, 2018 | Articles, Equipment, Welding

Buster Boats The future of Power Boating World-class aluminium welding precision with Kemppi X8 MIG Welder Buster Boats are manufactured at the Inha Works located in Ähtäri, Southern Ostrobothnia region of Finland. The boat range varies from four meters to over...

by Graham Fry | Oct 17, 2018 | Articles, Publications, Resources

Abstract In fabrication or construction, the goal is higher product quality with improved performance. This is especially important with relation to the GMA and TIG welding processes. I have heard many people comment to me that shielding gases only protect the welding...