MIG welding of aluminium can be performed in the short, spray or pulsed arc. The advantages of the pulsed technique are that spatter formation is reduced and a wire electrode with the next largest diameter can be used. The larger diameter wire is easier to feed and, at an identical melt-down rate, has a smaller surface area. Consequently, fewer impurities and less moisture are introduced into the weld seam via the wire.

Argon is by far the most frequently used shielding gas for MIG welding of aluminium. It has impressive all-round properties and can be used for all types of arcs and in all positions. Further improvement can be achieved by using Alushield®mixtures.

Performance Line® gases are used in cases in which higher quality seams and increased welding performance are required. All gases in the Alushield® series contain helium, which makes the arc hotter, broader and more stable.

Benefits of using Alushield®

- Reduced porosity

- Improved penetration, prevents lack of fusion

- Higher welding speeds

- Better gap bridging

- Less/no preheating of thick-walled components

- The more uniform heat input and better directional stability, facilitates the welding of components of different thermal conductivity, for example, in differing material thickness.

- Reduced notch effect and better distribution of forces thanks to wider, flatter weld beads.

Tips for MIG welding when shielding gases contain helium (Alushields)

Arc voltage

A higher helium content requires a higher arc voltage at an identical arc length.

Bead shape

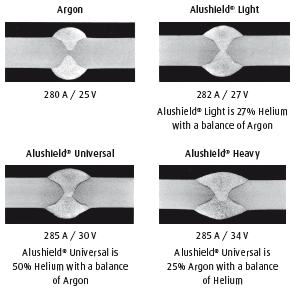

A greater helium content results in a broader and flatter seam at the same welding speed. The ‘argon finger’ is less pronounced and fusion penetration is rounder and deeper. This is advantageous, particularly in the case of dynamic loads.

Shielding gas flow rate

Helium is lighter than air. This has to be taken into account both when measuring throughout and when adjusting the minimum shielding gas flow rate..

GMA Welding of Aluminium Argon versus Alushield® Shielding Gases

Parent metal EN AW-5754 [AlMg3] t = 10 mm

Filler metal ISO 18273 – S Al 5183 (Al Mg4.5Mn) ø = 1.6 mm

BOC – A Member of the Linde Group, Mr Kyle Scott Market Manager – Welding and Industrial Gases, South Pacific

E-mail kyle.scott@boc.com