by Graham Fry | Jan 1, 2016 | Job Knowledge

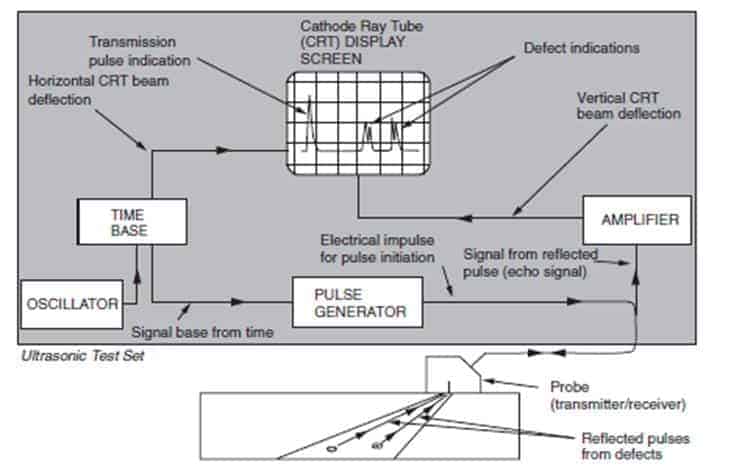

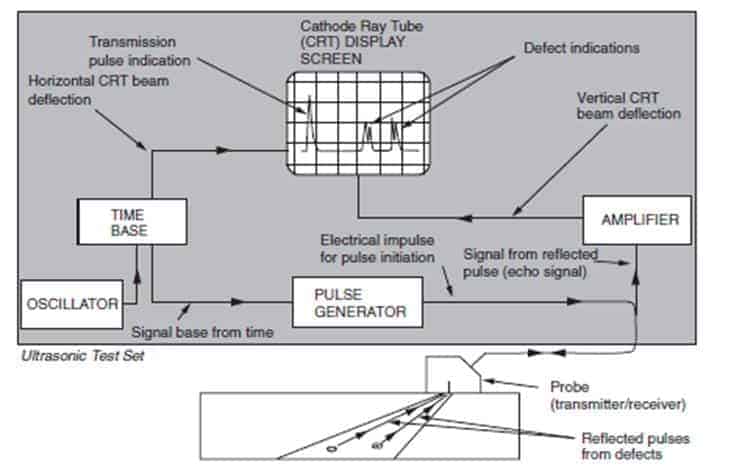

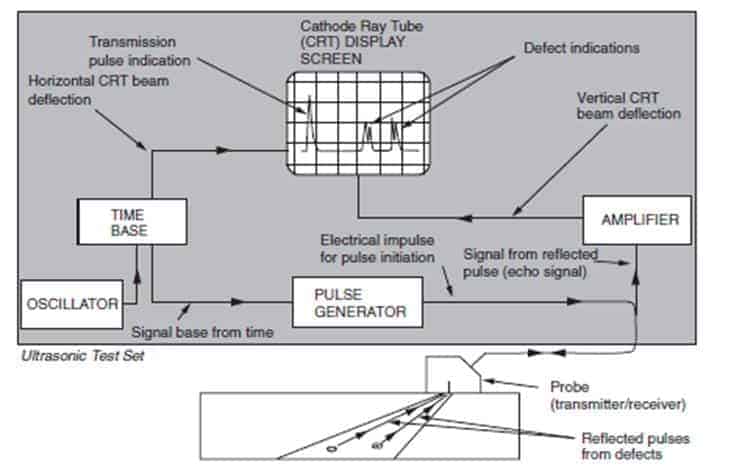

Ultrasonic Examination Part 1 Ultrasonic examination uses the same principles as the sonar used for the detection of submarines – a sound wave is emitted from a transmitter, bounces off any objects in its path and is reflected back to a receiver, somewhat similar to...

by Graham Fry | Jul 1, 2015 | Job Knowledge

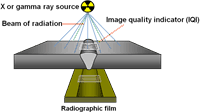

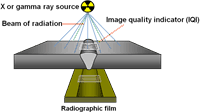

Job Knowledge – Radiography Radiography is one of the best know processes for reliably detecting buried imperfections – a so-called volumetric detection method. The first such method to be used in manufacturing to determine the quality of fabricated components...

by Graham Fry | May 1, 2015 | Job Knowledge

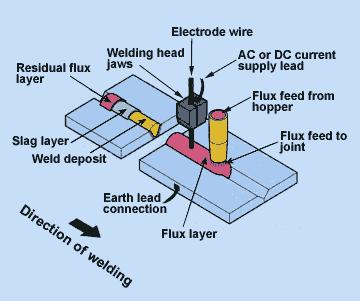

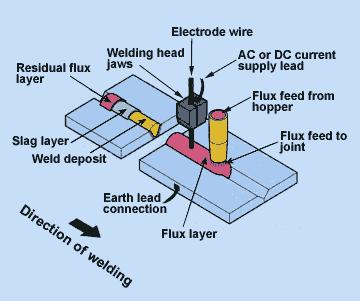

Submerged Arc Welding The first patent on the submerged-arc welding (SAW) process was taken out in 1935 and covered an electric arc beneath a bed of granulated flux. Developed by the E O Paton Electric Welding Institute, Russia, during the Second World War,...

by Graham Fry | Jan 1, 2015 | Job Knowledge

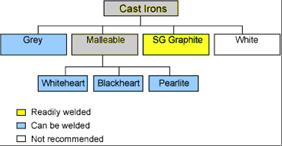

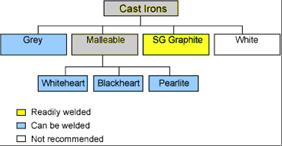

Cast irons are iron based alloys containing more than 2% carbon, 1 to 3% silicon and up to 1% manganese. As cast irons are relatively inexpensive, very easily cast into complex shapes and readily machined, they are an important engineering and structural group of...

by Graham Fry | Jan 1, 2015 | Job Knowledge

In arc welding, as the weld metal needs mechanical properties to match the parent metal, the welder must avoid forming defects in the weld. Imperfections are principally caused by: poor welder technique; insufficient measures to accommodate the material or welding...

by Graham Fry | Sep 1, 2014 | Job Knowledge

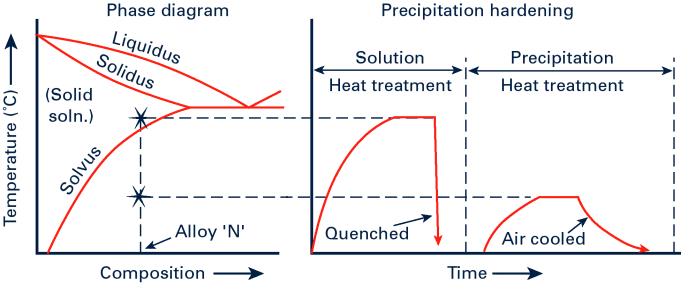

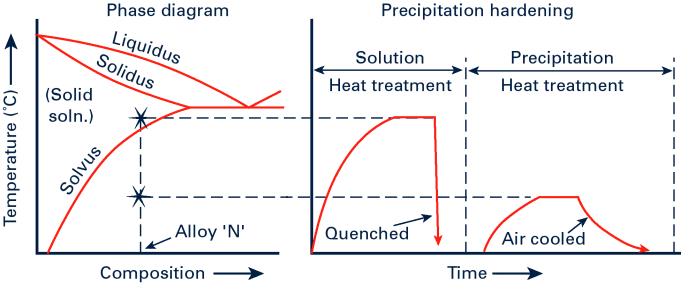

Precipitation or age hardening There are several methods that may be used to increase the strength of a metal; alloying, quenching of steel, work hardening, and one very specific form of heat treatment, that of precipitation or age hardening (the two terms are...