Progress of the AWITM

Certification

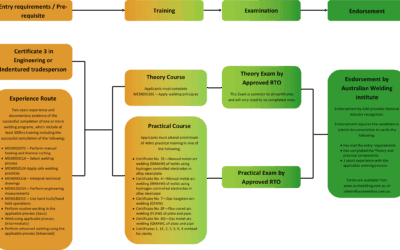

A key responsibility of the AWI™ is to provide a credible, transparent and user friendly welding qualification system for its members. To do this the AWI™ earlier established an Educational and Certification Working Group (E&C) to meet the following primary objectives:

- To undertake, arrange and promote education, training, qualification and certification for the benefit of members of the Institute and the welding industry as a whole

- To work closely with Australian TAFE bodies, Registered Training Organisations (RTO’s) related government agencies and departments to enhance National training agendas.

AWI™ actively supports and promotes the AS 1796 and AS 2214 Welding Supervisors qualifications and encourage all members and the Metal Fabrication Industry to embrace these qualifications. AWI™ has established an alliance with a number TAFE Colleges around the country and takes pleasure in supporting and promoting these Colleges and programs and are now endorsing Welder Qualification AS 1796 Certificates 1 – 9, Welding supervisors AS1796 and AS2214.

Application forms are available through selected TAFE Colleges and from admin@welding.org.au.

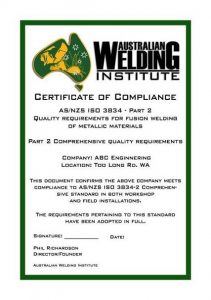

Compliance to AS/NZS ISO 3834 – AWI™ Guidance for Fabricators

The AWI™ has received some information revealing a high degree of confusion regarding Certification for AS/NZS ISO 3834 Quality Requirements for Fusion Welding. Therefore we have decided to re-print a previous guidance note.

Certification

Certification for AS/NZS ISO 3834 Quality Requirements for Fusion Welding is not required. As a standard, AS/NZS ISO 3834 simply lays down requirements for compliance. It is not a mandatory standard to be enforced by law.

A fabricator wishing to comply with 3834, can simply consider the relevant sections of the standards and satisfy themselves of their compliance, which they can then declare to potential customers. As part of this declaration, they are required to detail the documents used and the controls implemented.

Developing a competitive edge

Compliance with 3834 provides a global recognition of a fabricator’s capability, can reduce costs associated with rework, wastage etc. and can enhance a company’s ability to sell its products in both domestic and international markets.

Improved client confidence

Improved client confidence

AS/NZS ISO 3834 contains three levels of quality requirements and the appropriate level for your company will depend on the degree of complexity of the Company’s welding operations.

In an endeavour to increase your company’s capability in the welding quality market, AWI™ can assist in 3834 compliance after completion of our application document by:

- A review of the application documentation.

- AWI™ will conduct an assessment of your company’s current quality system, procedures etc.

- Determining which level of welding quality is appropriate for your company and which is in the most practical for your company to achieve and maintain.

The outcome of the AWI™ assessment will determine if your company’s system is in need of add itional controls and procedures or is already successful in compliance to the relevant section/s of 3834.

itional controls and procedures or is already successful in compliance to the relevant section/s of 3834.

We can assist in building a 3834 document structure and develop the required controls and procedures or fill in any gaps to your existing quality structure.

Successful applicants will be issued with a “Certificate of Compliance” indicating which level of compliance has been achieved. Certification can be addressed at a later stage if the company decides it wants to address this option.

For further details contact:

Phil Richardson on: 0438 991 860 or contact admin@welding.org.au

AWITM Certification assists member achieve their goal

I was given a start in engineering sector by my current employer GF Engineering in 2007 fresh off the streets with no prior experience. Initially recruited for the drawings department to produce shop detail drawings and isometrics, I was based in the same office as our Welding Supervisor (Trent Groves). GF Engineering invested the time and patience in me and provided the necessary in house training to develop me within my role.

Over the years I worked closely with Trent and learnt many aspects of the industry and the steps involved to produce a high standard product. I also began to learn the various codes and client specifications that we were working to. After a 2 year stint in Project Management, I moved back into the Quality office to help reduce the workload of Trent – where I became more involved in the day to day running of the Quality Department.

I attended Challenger Tafe once a week at night after work for 2 years, completing the Welding Supervisors course, where I gained the necessary theory and practical experience to be eligible to sit the Supervisors Exams.

Trent eventually moved on from GF in mid-2012 and I was asked to take over his role as Supervisor and Quality manager. Over the next 18 months I began to grow in confidence in my abilities and knowledge and contacted the AWI in November 2013 to sit my AS2214 Supervisors examination.

The ‘A’ paper was detailed and covered a wide range of aspects from the industry including; Welding Processes and Technology, Metallurgy, Quality Processes and Safety. Whilst in depth, all questions were relevant to today’s practices and standards. The ‘B2’ paper was based on AS 1554 Parts 1 and 2 and again was in depth, but designed in such a way that someone with sound knowledge and experience in the codes could manage all the questions within the timeframe allocated.

I thank that AWI for being flexible and allowing me to sit both the papers back to back on the one day. It was an enjoyable process and the feedback and level of service from the AWI has been outstanding.

I look forward to sitting the AS1796 Supervisors exams through them in the near future.