In April 2017, the WTIA (Welding Technology Institute of Australia) recently put out an article in their publication ‘Weld Connect’ which had the heading ‘What is a supervisor?’

The article began with the opening “Most people know what welding supervisors are’ and continued on to state that supervisors are ‘low level management’.

Contrary to the discussion set out by the WTIA, the AWI would argue, that in our experience, a large number of stakeholders in the fabrication industry have a ‘broad idea’ of the duties of a welding supervisor but in actual fact do not have any in-depth knowledge of the duties that a competent welding supervisor should be performing.

It is hard to understand the additional statement from the WTIA that “…supervisors are low level management..”.

The AWI believe that a competent welding supervisor performs a crucial role in the quality assurance of fabricated products, as much as the design engineer or the production manager and these roles could be considered at least front line management but the role is akin to middle level management.

To give the reader some background, over many years, there was much debate and argument between the MSA (Manufacturing Skills Australia) and the WTIA as to who should characterise, and ultimately develop/define the competencies required for welding supervisors.

The MSA (unfortunately a now disbanded organisation) held to their mandate and, in conjunction with industry skills councils, developed the competency units for welding supervision.

These competency units were arranged under a system of training packages, which replaced the national, broader based modular system of training and are underpinned by ‘pre-requisites’.

The pre requisites were put in place to ensure that a welding supervisor had completed the necessary groundwork i.e. trade experience and welding training etc. to enable them to perform the required tasks.

So the framework consists of:

- A system of training packages,

- Pre requisite training (entry requirements)

- Clearly defined skills and knowledge

Under the Australian Quality Training Framework (AQTF), Registered Training Organisations (RTO’s) are obligated to ensure students have the necessary pre requisite training prior to starting their welding supervision education. This ensures the candidate exits the welding supervision course and has the broad knowledge and skills that competent welding supervisors require, to be able to perform the role they are employed to do.

The AWI has observed first hand, and has taken many comments from its industry members regarding a progressive decline in the competence of welding supervisors over recent years. The question is “why might this be occurring”?

The AWI believe that some of the key factors are as follows:

The WTIA is an influential organisation within several of the Australian Standards committees, including those that develop:

- AS 1796 Certification of welders and welding supervisors and;

- AS 2214 Certification of welding supervisors – Structural steel welding.

Both these standards have set their own entry criteria for welding supervision which appears to be independent and contrary to the competency units mandated under the AQTF.

As an example, the latest two revisions of the above standards allow anyone with “A qualification in engineering, metallurgy or welding” to have direct entry without ANY practical welding experience i.e. no pre-requisite training.

The AWI asks these simple questions:

- How can a person with a qualification in metallurgy (or perhaps NDT certification) be a competent welding supervisor, when they have no practical experience in welding?

- How can such a person have an in depth understanding of how welding defects occur when they may not have been at the ‘hot end’ of the various methods of welding?

- How will they be able to ensure welding machines are set up correctly and safely?

- Could they train their workshop staff or demonstrate the use of an oxy-fuel set?

- Would they be competent to make decisions on a fabrication build sequence?

- Are the able to review welding procedures and make practical comments

In the experience of the AWI, it is a very simple answer, THEY CAN’T, which is perhaps why there appear to be welding supervisors, currently certified under AS 1796 who are ill-equipped to do the job they are employed to do.

Additionally, the Introduction of IIW qualifications may have compounded the decline of AS 1796/AS 2214.

For a number of years the WTIA heavily promoted certification of IIW qualifications (they are the only organisation allowed to do so in Australia under the rules of the IIW) and they made the decision to not offer AS 1796/AS 2214. However this appeared to cause a period of great confusion within the industry until they accepted that industry understood and wanted AS 1796/AS 2214.

Lately, there has been an attempt to combine the IIW International Welding Specialist (IWS) and AS 1796 which the AWI believe has further contributed to the dilution of AS 1796/2214.

Whilst there are some similarities between IWS and the two Australian standards, there are as many differences. One stand out difference is that the IIW syllabus is based on ISO and European (EN) standards, which is great for the twenty seven countries that presently make up the European Union but unfortunately they are not widely used in Australian welding fabrication. AS 1796 and AS 2214 are derived from the AS 1200 and AS 1554 suite of standards respectively.

Another significant difference is the entry requirements.

The AWI understands the fact that Australian Standards are a minimum requirement, we also understand the importance of underpinning knowledge to ensure competence, which is why we have modified our process/system to overcome the conflict that exists between the Australian standards and competency standards.

So what is our attempt to reverse this apparent decline?

Firstly, our focus is on providing a rationed / streamlined alternative to the overcomplicated system currently on offer.

Secondly ensure those sitting the examination have the necessary underpinning skills and knowledge.

Finally ensure the examinations are written in such a way that reflect the roles and responsibilities of welding supervisors in Australia.

So our point of difference is;

The AWI issues AS 1796/AS 2214 welding supervisor certification, it does so in accordance with both the intent of the Standards and in line with the AQTF. And while we do not exclude engineers or NDE technicians as such, from gaining a welding supervisor qualification, we have mandated that applicants without a trade background must complete the pre-requisite units with an approved RTO, therefore providing them with some practical experience. Essentially, the AWI have elected not to allow direct entry of Engineers and NDE technicians without this requirement.

Similarly candidates that have followed the IIW route to certification must show evidence of having gained the appropriate entry requirements.

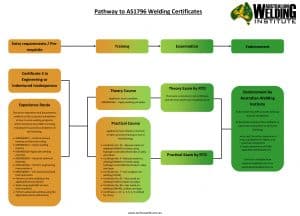

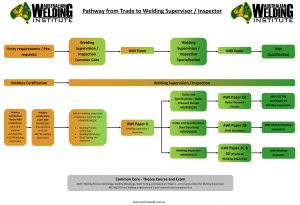

For more information on how you can achieve the AWI welding supervisors qualification email admin@technoweld.com.au or review the ‘Pathway to Certification’ below.