Four Steps to Proper Nozzle Selection

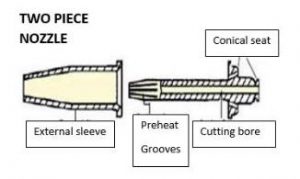

- Choose One-Piece or Two-Piece Nozzle: Acetylene – one-piece nozzle always. Other Fuel Gases – two-piece nozzle provides most efficient operation for normal cutting. One-piece nozzle extends life where heating is very severe.

- Choose Series: ANM, ANM-E, PNM, PNM-E, AFN nozzles. Elite 6 combination torch, DH Elite, and NM cutters.

- Choose Preheat Capacity: Choice of nozzle depends on preheat capacity. Steel coated with rust and scale, as well as bevel cutting, requires heavy preheat.

- Choose Size: Select size recommended for thickness of steel to be cut. Oversize nozzles waste gas. Use oxygen pressure recommended for nozzle.

Nozzle Selection

ANM PNM®Cutting Nozzles

- Hard drawn, electrolytic, tough pitch copper used in one-piece nozzles – withstands heat and wear – outlasts any copper alloy nozzle

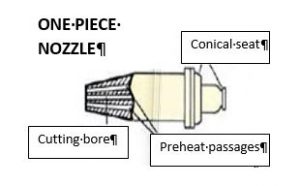

- One-piece nozzle has triple swaged interior – gas passages are mirror smooth with internal angles rounded for non-turbulent, more efficient gas flow – clean, smooth cuts with minimal kerf

- Preheat ports are closely spaced around cutting orifice for greater concentration of preheat flames

- Long, parallel preheat passages – permit re-dressing nozzle without affecting performance

- One-piece nozzle is a single piece of solid copper – provides maximum cooling – recommended always for acetylene, and for other fuel gases when heat exposure is unusually severe

- Two-piece nozzles – recommended for high efficiency with fuel gases other than acetylene – solid copper, heavy-wall external sleeve and brass internal sections can be ordered separately to minimize replacement cost

- Conical seats – instant aligning provides tight seal, prevents leaks around nozzle nut.