REVOLUTIONARY SAW TECHNOLOGY FOR ENHANCED PRODUCTIVITY

Want higher productivity?

Increased capacity and greater cost efficiency?

Is welding a critical part of your production process – and does it cause a bottleneck?

If so, ICE™ is the solution.

Want to increase capacity within your existing production footprint?

ICE™ can boost output significantly without need for expensive investment in new welding systems and extra capacity. No need for additional skilled welders.

Need to invest in new production systems?

Look no further. The combination of ESAB’s ICE™ technology, welding consumables and know-how offers the optimum welding solution.

Enjoy the increased productivity from shorter production times and the most cost-efficient Submerged Arc Welding. The market is yours for the taking!

ICE™ saves energy and the environment

ICE™ reduces your energy requirement, to ensure a smaller carbon footprint, greener production and lower costs. Unlike conventional SAW methods.

The coolest innovation since the introduction of SAW technology. ICE™ puts excess heat to work – for greater productivity!

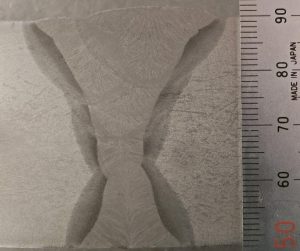

ICE™ technology (patent pending) is as simple as it is brilliant. ICE™ exploits the excess heat generated by the welding process to melt an additional non- powered welding electrode – the Integrated Cold Electrode. This yields significant productivity benefits without increasing heat input.

Up to 50% higher deposition rate

Submerged arc welding is already the most productive welding process. But as with any other welding process, the need to limit heat input inhibits productivity. Instead of adding more energy, ICE™ utilises the excess heat available to melt more wire. This boosts productivity by up to 50%, depending on the application.

ICE™ technology enables the use of tandem welding in root passes, for improved penetration and high productivity and eliminating the need for back gouging. High Deposition Root can increase productivity up to 100% in root welding, depending on the application. The increased deposition rate can also be utilised to increase welding speed.

high productivity and eliminating the need for back gouging. High Deposition Root can increase productivity up to 100% in root welding, depending on the application. The increased deposition rate can also be utilised to increase welding speed.

This can significantly improve productivity in applications where welding speed is the key to maximising productivity.

Higher welding speed

Adjusting the ratio of “cold wire” used for cap runs makes it possible to produce a flatter cap to the weld. This increases fatigue resistance and reduces the need for post weld treatment. Just one more boost to your productivity.

Reduced energy consumption

Reduced flux consumption

Welding is an energy intensive manufacturing operation. The ICE™ process enables an increase in deposition rate by up to 50%, without adding more energy. This combines environmental benefits with significantly reduced energy consumption.

The significant productivity improvement provided by ICE™ enables many applications to be completed with fewer runs. In this way, flux consumption can be reduced by up to 20% when welding with a 50% higher deposition rate.

| Applications

Some of the many applications that can benefit from ICE™ technology are: On-and-offshore wind tower manufacturing Offshore fabrication Pipe welding General heavy fabrication Shipbuilding

|

Comparison of deposition rate for ICE™ and other methods.

Deposition rate

ICETM

Twin DC+

Single DC+

Single power-source and welding-head solutions

Deposition rate

DC + AS + ICETM

DC + Twin AC+

DC + AC

Two power-source and welding-head solutions (tandem welding).

ESAB – the optimal SAW solution

A world-leading supplier of Submerged Arc Welding systems, ESAB has decades of experience in supplying innovative applications to the most demanding customers.

supplying innovative applications to the most demanding customers.

Our wide range of welding consumables, partnered with ICE™ technology, delivers the most productive SAW solution for your application.

You can rely on the full support of ESAB’s process specialists in developing optimised welding procedures and maximising the multiple benefits of ICE™ technology.

PATRICK GEOFFROY

Sales Manager Automation Cutting & Welding (ESAB) – South Pacific

CIGWELD PTY LTD – An ESAB Brand

71 Gower Street, Preston 3072, Victoria, Australia