The Safe Way To Onshore and Offshore Welding

Oil and Gas Pipelines

Globally wanted. Locally owned. Dangerous and non-renewable. Inevitable part of our societies and our lives. Oil and gas it is.

Kempii are keeping you on the safe side

Tested in the Atlantic Ocean, Arabian deserts and Siberian forests, Kemppi is the qualified partner for the most demanding oil and gas welding projects. Our customers excel by using our reliable equipment with optimized arc characteristics and multi-site welding management software with advanced documentation collection and management. The equipment and management software help you to meet the customer requirements and global standards, such as API, ASME, AWS, ISO and COST. Kemppi is the safe way to welding.

Pipelines

The quality of pipe welds correlates strongly with the productivity of pipeline projects. The demand for larger diameter pipes with higher strength steel is increasing. Need for thinner wall thickness and faster but reliable welding methods is obvious.

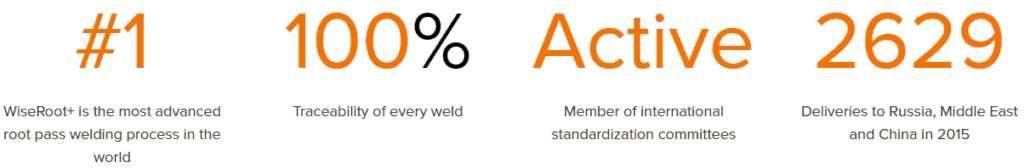

Kemppi has developed the most advanced root pass welding process in the world. The Kemppi WiseRoot+ process enables welding without backing, which saves backing material and labor time costs. It results in high class welds with easy control, and also decreases welding time that contributes largely to the project’s productivity.

Oil rigs

When operating in the middle of a stormy sea, the word “extreme” gets a whole new meaning. Completing a welding project at the oil rig demands extensive documentation and perfect, durable welds. Kemppi solutions offer 100 % traceability of every weld even in extreme conditions. The number of welding imperfections is minimized with Kemppi. Also, the probability of corrosion is reduced because of excellent welds and traceability. All these increase directly your productivity.

Refineries

Kemppi has been the partner in many refinery building projects. Our intelligent equipment adjust your welding procedure according to the welded material and the pipe diameter, liquid influx/flow and pressure. For your welders, our training is an easy way to gain the needed knowledge and skills to do their jobs safely.

Read Kemppi’s white paper on advanced pipe welding with gas metal arc welding.

[maxbutton id=”1″ url=”https://www.kemppi.com/en-US/offering/discover/oil-and-gas-pipelines/?utm_source=email&utm_medium=nurturing&utm_campaign=general&mkt_tok=eyJpIjoiT1RCa01EQTNPR0U1WVRFNCIsInQiOiJqOTk2SVNaak9JTGRTZEF4dzZ2RGE0eFwvMXJ2R1BTR1VuazBGc2Q0bXFaWmJQVThzQXVSZ2tmTFdLc3ljNDU3VnhEUkVxU3BoN1M0RjI1clRtc3NLeXFjMWVTaVwvMTlveDFaRGQ0WHRXWjREK3B3RzlwR25FR2dlQktGUVJMakVaVjhVamlVM2gyVHp3cU41RFREUVVZdz09In0%3D&form=1013″ text=”Download Now” ]