by Graham Fry | Sep 1, 2014 | Job Knowledge

When it is not possible to place the entire component in a furnace for heat treatment (because of the size of the fabrication, circumferential welds in a pipework system or when installing equipment on site, for example), then a local PWHT may be the only option....

by Graham Fry | Sep 1, 2014 | Job Knowledge

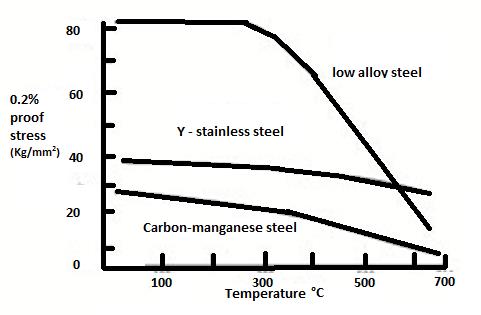

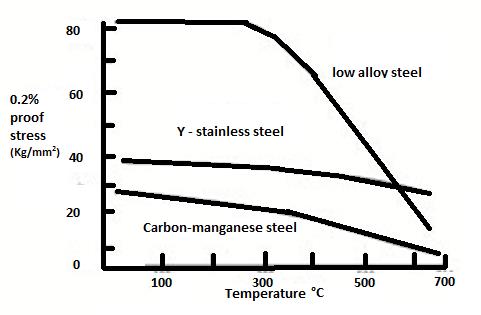

Part 1 of this series of articles gave definitions of some of the heat treatments that may be applied to a welded joint and dealt with the operation of stress relieving a ferritic steel assembly. The temperature range within which stress relief takes place will also...

by Graham Fry | Sep 1, 2014 | Job Knowledge

Heat treatment is an operation that is both time consuming and costly. It can affect the strength and toughness of a welded joint, its corrosion resistance and the level of residual stress but is also a mandatory operation specified in many application codes and...

by Graham Fry | Jul 1, 2014 | Job Knowledge

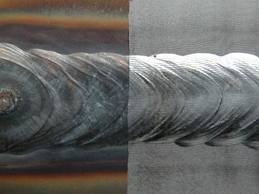

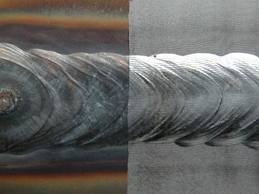

Welding of austenitic stainless steel – Part 1, dealt with the metallurgy of austenitic stainless steels and some of the welding problems that may be encountered. Austenitic stainless steels can be welded with all the commercially available welding processes....

by Graham Fry | Jul 1, 2014 | Job Knowledge

Welding of austenitic stainless steel – Part 1 There are a number of different types of steels that may be referred to as ‘stainless’; previous articles have considered ferritic and precipitation hardening steels for example. It is therefore...

by Graham Fry | May 1, 2014 | Job Knowledge

The previous two articles dealt with the mechanics of costing a weld: how to calculate the weld volume and how to calculate the amount of welding consumables required to fill a weld preparation. The final step in costing a weld is to determine the length of time to...