Kemppi’s first-ever double-pulse TIG process is delivering considerable welding benefits for the welders who have used it thus far!

Developed by leading international welding equipment manufacturer, Kemppi, the double-pulse TIG is a new TIG welding process that can be used to gain quality and productivity improvements in direct current welding (DC-) when compared to conventional pulse TIG processes.

To date, several pulse methods have been developed, with the techniques available now ranging from unshaped pulse with a roughly 1 Hz frequency to shaped pulses with a frequency measured in kilohertz. These pulse processes increase productivity and especially, quality, even though the improvements in productivity are often either minor or application-specific.

With the launch of the new MasterTig range, Kemppi’s first-ever double-pulse TIG process offers several benefits in terms of efficiency and quality for multiple TIG welding methods.

The new process combines two distinct DC pulse methods. It uses low speed (0.2-30 Hz) and high speed (100-400 Hz) negative direct current pulses simultaneously. As the parameters for the high-speed pulse are determined in line with a readymade welding program, the welder does not have to adjust them. However, the parameters for the low-speed pulse are adjustable, although the factory settings are suitable for general welding.

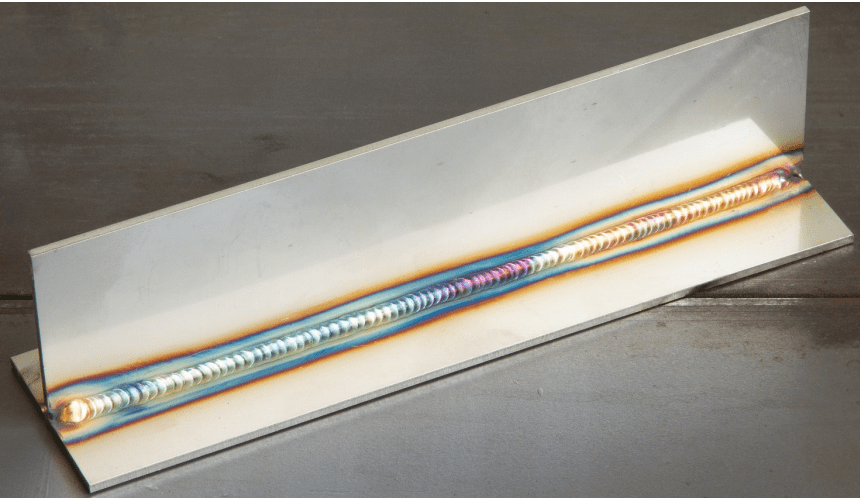

The image shows that, unlike double pulse TIG’s narrower arc, the wide arc generated by a low-speed pulse (on the left) lacks the ability to melt the corner at high travel speeds (450mm/min). The narrow and stable arc of the double pulse process on the right, performed well at this travel speed.

Numerous mechanised and manual welding tests of the new method were conducted. The results of the new process were compared with the results of the conventional pulse-TIG processes (low and high-speed pulse) and the quality and productivity improvements were considerable.

By combining the properties of two distinct pulse methods, the process also delivers the benefits of these two pulse types. Thanks to the high-speed pulse, the arc in double-pulse welding is narrow, well-focused, rigid and easy to target. In addition, the temporary high power generated by the low-speed pulse enhances the fluidity of the weld pool, enabling a higher travel speed with certain joint types (for fillet and overlap welds). The low-speed pulse’s temporary low power can be used in the solidification of the weld pool, which improves properties connected with position welding.

Benefits of Double-Pulse TIG Welding Process

The Kemppi double-pulse TIG welding process offers numerous benefits including:

- A narrow and stable arc, which is easy to direct to a corner

- Higher travel speeds than in a conventional TIG process

- Lower welding currents

- Greater tolerance of an inconsistent root gap when compared to a conventional TIG process

- Consistent travel speed

- Tack welds of consistent quality

- Improved suitability for position welding when compared to those offered by TIG processes

- The ability to achieve a fish-scale appearance without the need for a special welding process

- The option of producing differential penetration

Applications

As the double-pulse method brings together the benefits offered by low and high-speed pulses, it is suitable for a wide range of applications and in particular:

- Work involving thin sheets

- Fillet and corner welding

- Welds with strict requirements for visual quality

- Stainless steels

- Metals that require low heat input, such as high-strength, duplex and super austenitic steels

- Challenging non-ferrous metals handled with DC welding, such as titanium

The new welding process is easy to apply and typically does not require testing for the correct parameters or any practicing in advance.

For more information or a demonstration of the new Double-Pulse TIG welding process call Kemppi Australia on (02) 8785 2000 or email sales.au@kemppi.com