While certification to ISO 9001 provides documented evidence as to the quality of your business management systems, it does not demonstrate in any way the capability of your workforce or business to undertake special processes, such as pipe, or pressure vessel welding, to the levels required by an increasing number of customers operating in the world’s specialist markets.

ISO 3834 part 1, the criteria required for quality requirements for fusion welding of metallic materials parts is laid out. This is recognised by the Australian Welding Institute (AWI) and international standards worldwide as the benchmark for a high-quality welding process.

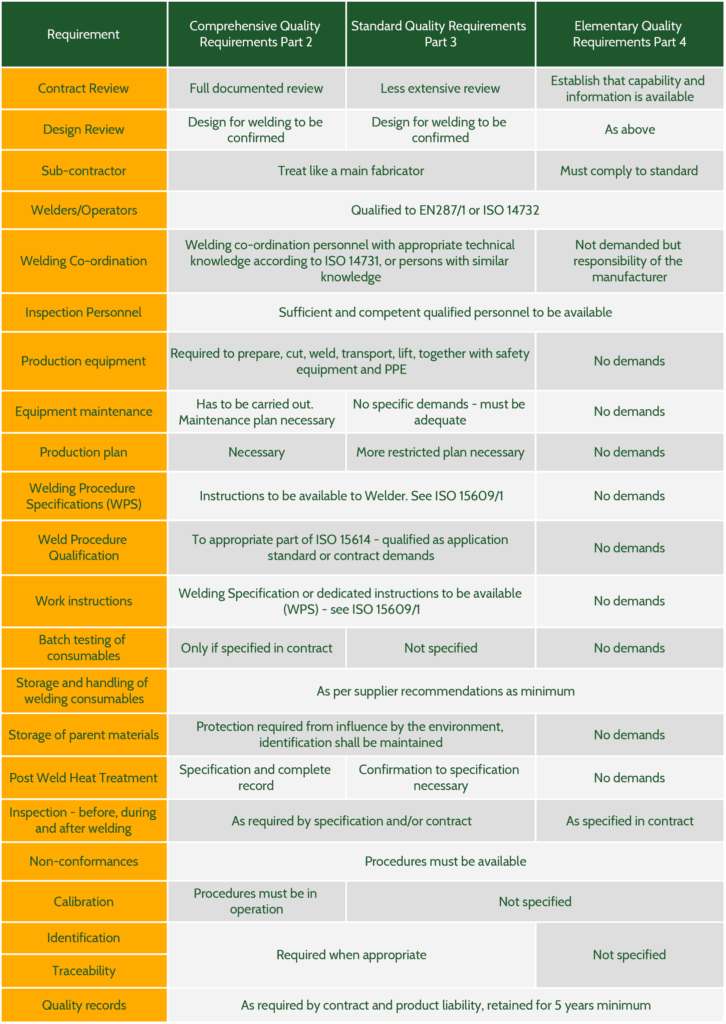

There are three levels of welding management 3834 part 2 – Comprehensive, 3 – Standard and 4 – Basic. The level the fabricator selects is based on the type of work they do and their clients’ requirements.

It should be of particular interest to companies involved in the welding of heat exchangers, pipelines and other pressure equipment, as well as those wishing to operate in the petrochemical industries, civil engineering, public infrastructure and defence sectors.

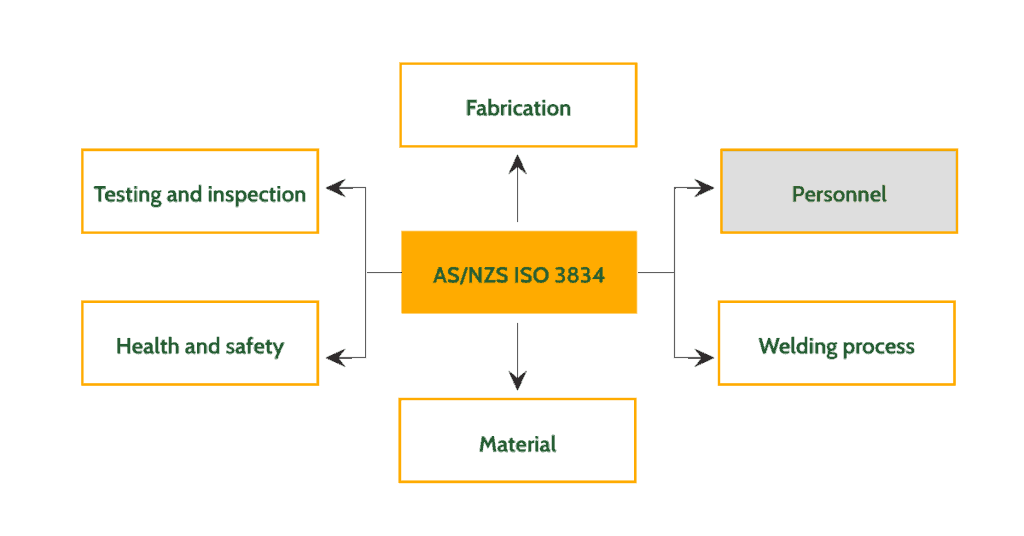

AS/NZS ISO3834 covers all aspects of the welding operation from pre-award technical review through to documentation and delivery conditions.

The benefits for certified fabricators

Although ISO 3834 can operate alongside 9001, it is not reliant on compliance with 9001.

Stand-alone, ISO 3834 compliance can provide a lot of positives for welding enterprises and their welding teams. Certification provides documented proof of your fabricator’s ability to produce high-quality products following a welding management system to the most stringent requirements.

It allows even the firms to be entered on the AWI register, hence boosting the chances of involvement in higher-value projects requiring ISO 3834 compliance.

Additional Benefits of ISO 3834 Certification

Although certification is not mandatory, it does provide a number of business benefits over companies that are not certified.

In a world where high-quality workmanship is paramount, maintaining certification provides for national and international companies to approach your business, safe in the knowledge you have the capability and credibility to undertake the required processes audited against a recognised standard in 3834.

All personnel involved in the certification process from the shop-floor to supervisors and higher management will benefit from increased process control, reducing rework and having defined clear instructions.

Certification provides the opportunity to expand your business operations, including sub-contract work for major international players such as the special process welding required in the petrochemical and civil engineering industries. Once the certification has been achieved, your business should operate more efficiently. You should notice reduced costs and overheads due to reduced production time and minimised reworks.

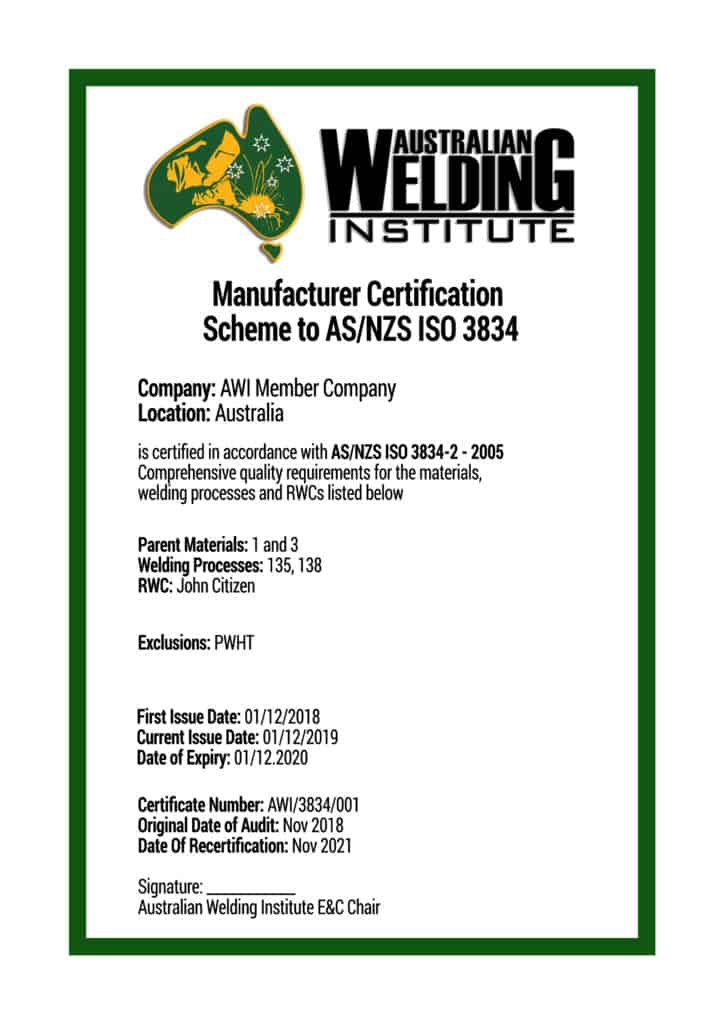

Technoweld can design and implement your ISO 3834 system to be certified by the Australian Welding Institute (AWI). The improved operational procedures and the high quality of completed products will increase customer satisfaction and likely lead to an increasing order book and higher profitability.

Hi,

I am looking for ISO 3834:2 accreditation.

Can you please provide quote and further details.

Thanks.