Types of electrodes and their compositions

Many types of manual metal arc (MMA) electrodes are available on the market. Depending on the main constituent of their flux, they are grouped into three categories: cellulosic, rutile and basic.

All electrodes consist of a core wire (typically 2.5–6mm diameter) coated by a flux. The core wire is generally made of low-quality riming steel and the fluxes contain many elements allowing refinement of the weld microstructure.

The composition of the flux impacts the electrodes’ behaviour. The main constituents of the different types of electrodes and the shielding gas created for each are described in Table 1 (Bowniszewski, 1979).

| Electrode type | Main constituent | Shielding gas created |

| Rutile | Titania (TiO2) | Mainly CO2 |

| Basic | Calcium compounds | Mainly CO2 |

| Cellulosic | Cellulose | Hydrogen + CO2 |

Table 1 Main constituent of the three possible types of electrodes and shielding gas created by its combustion.

MMA electrodes’ main characteristics have been extensively described (Bosward, 1980). The following paragraphs are a summary of general purpose electrode (rutile and cellulosic) characteristics of interest.

The rutile electrode

The difference between the E6012 and E6013 electrodes is that the E6012 covering contains sodium, while the covering of E6013 contains potassium. They can both run under direct current (DC+) but only the latter is suitable for running under alternative current (AC). Working with a constant current is recommended to counterbalance the unsteadiness of the welder’s hand.

With a high proportion of titanium dioxide (also called titania) the rutile electrode gives a smooth bead surface, easily removal slag and a smooth arc.

During the combustion, the flux coating will mainly create carbon dioxide. This flux also contains cellulose. Even though the cellulose content is far lower than for a cellulosic electrode (up to 10% according to Boniszewski), its presence, along with that of moisture, means that these electrodes produce relatively high levels of hydrogen: up to 25ml/100gm weld metal.

This restricts their use to mild steels with a thickness lower than 25mm and thin-section low-alloy steels of the C/Mo and 1Cr1/2Mo type.

Rutile electrodes can be used to weld in all positions apart from vertical down position. Deposition can be improved through the addition of iron powder, which leads to more metal being deposited at the same current. However, electrodes with added iron powder can only be used in a flat position.

Rutile electrodes have a medium penetration, quiet arc and create little spatter (Bosward, 1980). They create a large amount of self-releasing slag which requires little cleaning after welding.

They are probably the most widely used general purpose electrodes. However, these electrodes should not be used on structures where high toughness is required (Bosward, 1980). Table 2 summarises their mechanical properties.

| Impact value requirement (AWS as welded) |

Testing temperature | Yield strength requirement (MPa) | Typical tensile requirement (MPa) |

| E6012 | |||

| Not specified | 0°C | 330 | 430 |

| E6013 | |||

| Not specified | 0°C | 330 | 430 |

Table 2 Typical mechanical properties obtained with E6012 and E6013 AWS A5.1/A5.1M, 2012.

The cellulosic electrode

Similarly to rutile electrodes, the differences between E6010 and E6011 cellulosic electrodes are the electrical parameters used during welding and their type of covering.

The covering of E6010 contains sodium; E6011 contains potassium. They can both run under direct current (DC+) but only the latter is suitable for running under alternative current (AC).

The MMA process can be used in DCEN, DCEP or AC but again a constant current is recommended to counterbalance the unsteadiness of the welder’s hand.

The gas shield generated by cellulosic combustion contains hydrogen, carbon monoxide and carbon dioxide. Between 30 and 45ml hydrogen/100gm can be found in the weld. This has two consequences: good protection of the weld pool and a high level of diffusible hydrogen in the weld metal and heat-affected zone (HAZ). The high percentage of hydrogen is the cause of the high deposition rate and deeper penetration by the creation of the punchy arc (Clyne, 1984) for which this kind of electrode is well known.

Another consequence of the hydrogen content of the gas shield is the requirement for a higher voltage (around 70V). However, the high hydrogen content in the shielding gas is also this electrode’s main drawback. It causes a high level of diffusible hydrogen in the weld, which is one of the parameters influencing hydrogen cracking (also called cold cracking) if good practices are not followed and preventive actions are not taken.

The high hydrogen level means that any steel welded with these electrodes should have a very high resistance to hydrogen-induced cold cracking. These electrodes are mainly used on low-carbon, non-alloyed steel. They should be used only with due consideration of the steel composition, restraint and need for preheat.

One other advantage of cellulosic electrodes is their ability to weld in the stove piping (or vertical down) position. E6010 electrodes are sometimes called ‘stove pipe electrodes’. This position can enhance the weld and helps to improve efficiency and productivity, thanks to quick cooling of the slag.

This method of welding should be performed by an experienced welder who can put down welds in quick succession, to maintain a hot welding condition and enable hydrogen to escape. On thick-wall pipe, the welder can experience difficulty controlling the weld pool because of its increase in size and the risk for it to over-run the arc and flood the joint (Spiller, 1991).

It should be noted that any type of cellulosic electrode requires a highly skilled welder, so stove pipe welding especially should not been carried out without care and proof of competence of the welder.

The amount of spatter created will limit the use of very high current (Bosward, 1980). A large amount of fume is also produced by cellulosic electrodes (Welding and Cutting, 2013) but the amount of slag to remove after each weld is small.

The mechanical properties of the cellulosic electrodes are presented in Table 3. Impact values are available up to -30°C in the as-welded condition.

| Required impact value (AWS as welded) |

Testing temperature | Typical yield strength (MPa) | Typical tensile strength (MPa) |

| E6010 | |||

| 27J | -30°C | 330 | 430 |

| E6011 | |||

| 27J | -30°C | 330 | 430 |

Table 3 Typical mechanical properties obtained with E6010 and E6011, AWS A5.1/A5.1M, 2012.

Its characteristics of deep penetration, high deposition rates and ability to be used in vertical down position means that the main use for these electrodes is for cross-country pipelining, although they are used to a more limited extent for welding storage tanks.

In a more industrial environment the use of this type of electrode is usually restricted to the root pass of the welding procedure. After root pass, a hot pass should be deposited within the next ten minutes to limit the cooling of the welding pass and allow hydrogen to escape.

This limitation should be specified in the welding procedure specification. Again, these electrodes require a skilled welder. This is particularly relevant when working with a pipe of outside diameter below eight inches, because the vertical down welding position can be difficult.

Conclusion of the comparison

In accordance with European standard (EN 1011-2:2004) the necessary preheat temperature and duration can be determined depending on the steel’s carbon equivalent and the amount of diffusible hydrogen created by the electrode. This determines where electrodes are classified on a five-point scale, from A to E.

Category A corresponds to electrodes creating an amount of diffusible hydrogen greater than 15ml/100g of deposited metal.

Category E relates to electrodes creating an amount of diffusible hydrogen lower than 3ml/100g of deposited metal. Both types of electrode belong to category A for preheat determination.

According to Boniszewski (1979), despite the reasonable quality and toughness of the weld obtained with cellulosic electrodes (100J Charpy-V obtained at -10°C), because of the high preheat temperature required, they are usually avoided for high technology fabrication such as offshore structures or pressure vessels

Cellulosic electrodes are more difficult to use and consequently require a skilled welder. Their big advantage is the increased speed they enable through the stove pipe technique or vertical down welding – but not weld quality.

They are suitable in cases such as when large quantities of pipe must be welded or a lot of vertical down welding is required, not for one-off jobs. The speed of travel can be as high as 300mm/min.

In any case, the use of cellulosic electrodes is generally limited to the root run of a multi-pass procedure. The use of a hot pass is vital in the case of cellulosic electrodes.

The following table summarises the comparison and the previous conclusions.

| Characteristic | Rutile electrode | Cellulosic electrode |

| Current (A) | Lower | Higher |

| Voltage (V) | Lower | Higher |

| Penetration | Lower | Higher |

| Amount of spatter | Lower | Higher |

| Slag removal | Self-releasing | Need brushing |

| Cleaning | Very little required | Always needed |

| Position | All except vertical down | All including stove pipe/vertical down |

| Ease of use | Easy | Require skilled welder |

| Fume creation | Lower amount of fume | Greater amount of fume |

| Hydrogen cracking risk | Low risk if correct pre-heat | High risk |

| Single or multipass weld | Single and multipass | Multipass |

| Preheat precautions | Require preheat in accordance with BS EN ISO 1011-2:2004 | Require preheat in accordance with BS EN ISO 1011-2:2004 |

| Post weld heat treatment | Hydrogen bake out can be used to help diffusible hydrogen removal |

Table 4 Comparison of electrode characteristics.

Guidance and best practice to avoid hydrogen cracking in the case of cellulosic electrode use

Hydrogen cracking occurs at near ambient temperature if three conditions are met: diffusible hydrogen in the weld, tensile stresses and susceptible microstructure (Kihara, 1970).

Tensile stresses cannot be avoided but they can be reduced with a sensible design. The microstructure can be controlled to some extent by selecting material less sensitive to hydrogen cracking (with a low carbon equivalent [EN 1011-2: 2004]). Finally, the reduction of the diffusible hydrogen content in the weld can be managed by selecting a consumable with low hydrogen content (which is not the case with cellulosic electrode) or by improving the hydrogen release of the weldment.

The hydrogen content in the weld metal depends on the cooling rate from welding temperature (Folkhard et al, 1973). As a comparison, samples extracted after welding with cellulosic electrodes and cooled in still air have lower diffusible hydrogen content than samples quenched in iced water. The cooling rate can be decreased by an increase of preheat and interpass temperature.

When the thickness increases the degassing time (and the welding time) for the weld increases, and so the amount of degassing hydrogen increases. Also, the additional heat of the next run leads to degassing of the previously deposited bead and to a more refined microstructure. However, residual stresses will increase.

The cooling conditions of the root run are critical to the hydrogen content in the weld. Refining or reheating the second pass helps to release diffusible hydrogen.

Additional guidance and best practice in the use of cellulosic electrodes

First of all, only welders with recent qualifications specifically relating to the use of cellulosic electrodes should be allowed to carry out any welding activity with them.

A preheat identical to the one required for rutile electrodes should be applied before welding to reduce the cooling rate of the weld and allow for hydrogen release.

The use of cellulosic electrodes should be limited to the root run and always followed by a hot pass with another electrode to allow the removal of most of the diffusible hydrogen and refinement of the weld macrostructure. Additionally, single-pass fillet welds should be avoided as this is likely to increase the sensitivity to hydrogen cracking. This is because the HAZ hardness, and the amount of diffusible hydrogen, is likely to be higher without subsequent reheating from successive passes.

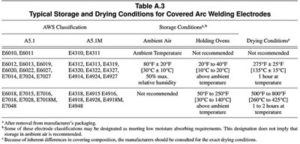

Cellulosic electrodes should not be dried as they rely on hydrogen in the atmosphere to shield the weld pool. They should be used directly from the manufacturer’s packaging. In case the electrode is damp it can be dried in an oven at 120°C. If electrodes become soaked they need to be discarded and thrown away. Guidance on consumable storage can be found in AWS A5.1/A5.1M.

AWS A5.1/A5.1M:2012, Table A.3 reproduced with permission of the American Welding Society (AWS), Miami, Florida, USA.

In case of high hydrogen cracking risk it is possible to post-heat (also called hydrogen baking) the weld by either maintaining the minimum interpass temperature or raising the temperature to 200–300°C immediately after welding, before the weld region cools to below the minimum interpass temperature (EN 1011-2: 2004).

Conclusion

Only welders with recent qualification to use specifically cellulosic electrodes should be allowed to carry out any welding activity with them. Use of cellulosic electrode should be restricted to the root run, before the weld is filled using rutile electrodes. The hot pass should be deposited a maximum of ten minutes after completion of the root pass. Preheat should be selected in accordance with BSI BS EN 1011-2, taking into account material grade and restraint of the weld.

References

ASME B31.3 A106 grade B.

AWS A5.1/A5.1M, 2012: ‘Specification for carbon steel electrodes for shielded metal arc welding’.

Boniszewski T, 1979: ‘Manual metal arc welding – old process, new developments, Part II: Understanding MMA electrodes, metallurgist and materials technologist.’ Vol. 11. No. 11.

Bosward I, 1980: ‘A guide to electrode selection, welder.’ Vol. 41, No. 210, pp10-13.

BSI BS EN 1011-2: ‘Welding —Recommendations for welding of metallic materials — Part 2: Arc welding of ferritic steels.’ 2004

Clyne A J, 1984: ‘Evaluation of low hydrogen electrodes for pipeline girth welding.’ British Gas R&D.

Folkhard, H, Schabereiter H, Rabendteiner G, Rettenbacher H, 1973: ‘New knowledge on the hydrogen content of welded joints as a basis for the crack free welding of high-tensile pipeline steel with cellulosic electrodes.’ International welding conference, pp39/44.

Kihara H, Terai K, Yamada S., Nagano, T, 1970: ‘Study on preheating temperature in welds of high strength steel structure.’ Trans Jap. Welding Society, 1, pp119/129.

Welding and cutting: ‘Selection of stick electrodes (part 1) welding and cutting.’ Vol. 123, No. 4, 2013.

Spiller K R, 1991: ‘Process options and manual techniques for welding pipework fabrications, Process pipe and tube welding.’ Ed: W Lucas. Publ: Abington, Cambridge, CB1 6AH, UK, Abington publishing; ISBN 1-85573-012-X. Chapter 1, pp1-20.