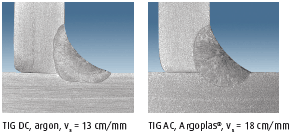

In TIG welding, the arc burns between the workpiece and a non-consumable tungsten electrode. To protect the electrode and molten pool from oxidation, both are shielded with an inert gas, generally argon. This welding process is suitable for all fusion-weldable metals. The type of current, polarity and shielding gas used depends on the base metal. TIG welding can be carried out both with and without filler metal.

Tips for when utilising additions of Helium or Hydrogen

The addition of hydrogen or helium is especially beneficial to heat distribution and heat transfer in the arc, particularly with TIG welding. The Performance Line® offers a broad range of specialty gases that, owing to their hydrogen or helium content, enable a distinct increase in productivity.

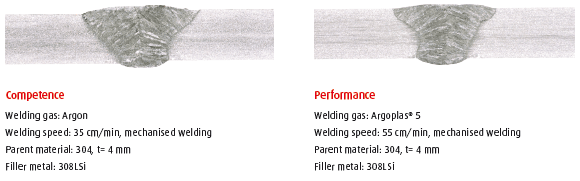

Agroplas®5 is primarily recommended for TIG welding of austenitic stainless steels and some nickel-based alloys. The hydrogen content in the gas permits more energy to be transferred to the metal. This, in turn, results in deeper penetration and/or greater welding speeds. The hydrogen content may be as much as 15%, although the realistic upper limit for manual welding is 5%. As a rule, gases with a higher hydrogen content are only recommended for mechanised welding, since it is more difficult to control the heat and the pool is very fluid. Gases containing hydrogen must not be used to weld aluminium or titanium alloys or steels sensitive to hydrogen since this can lead to greatly increased porosity or embrittlement.

Since helium (like argon) is an inert gas, the gas mixtures in the Alushield® series can also be used for aluminium alloys, all types of steel, and for gas-sensitive metals.

Stainshield® Duplex was developed especially for TIG welding duplex steels or fully austenitic materials. The addition of nitrogen causes the austenisation of the weld metal, which is particularly beneficial when TIG welding duplex steel without filler metal. These gases have also proven valuable for low-ferrite welding of high-alloy metals in the chemical industry.

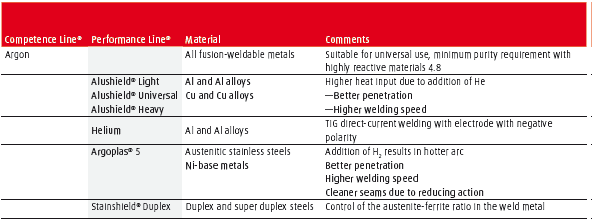

TIG Shielding gases at a glance

Argoplas®5 improves speed of welding and penetration

Manual welding of stainless steel 304, sheet thickness 4 mm

TIG Welding of Stainless Steel Argon versus Argoplas®5

BOC – A Member of the Linde Group, Mr Kyle Scott Market Manager – Welding and Industrial Gases, South Pacific

E-mail kyle.scott@boc.com