To confirm that a weld has been made to specification it is usually required to measure and often document the parameters that have been used. For arc welding the main parameters are as follows:

- Welding current

- Arc voltage

- Travel speed

These parameters can be used to calculate the heat input, which is derived from the arc energy. The other parameters which may be measured and recorded are as follows:

- Wire feed speed (for MIG/MAG) and other processes with a filler wire

- Gas flow rate (shielding, backing and plasma)

- Temperature (pre-heat, inter-pass and post-weld heat treatment)

In most cases the mean values of the parameters over the time of the weld can be recorded and used to calculate heat input. A simple meter can be used for this, but it is better for quality assurance to have documented values. A number of instruments exist which have been specifically designed for this purpose. Generally, they provide a paper printout with mean values over a second or so. Some of these instruments allow the length of the weld to be input so that arc energy (kJ/mm) can be calculated.

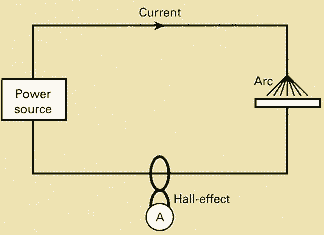

When measuring voltage and current it is important to do so correctly. Although current can be measured anywhere in the circuit, Figure 1, it is important to ensure that all the current passes through the cable and is not, for example, conducted elsewhere through the component or through a leakage path to earth.

Fig. 1. Current measuring technique, ‘A’ showing the connection for the sensor

Current is normally measured by a Hall effect probe clipped around the cable. The current rating and accuracy of the probe needs to be taken into account.

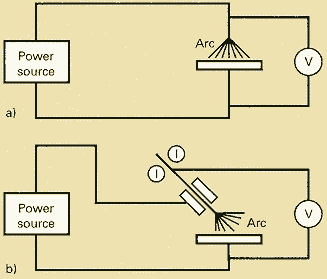

Voltage measurement is a bit more difficult to get right as the voltage will vary depending where the connections are made. For true arc voltage, it is important to measure as close to the arc as possible, Figure 2. For MIG/MAG, a connection on the drive rolls, back at the wire feeder, will suffice. However, the voltage measured across the arc will be lower than that measured across the power source terminals, possibly by several volts, depending on the length and diameter of the welding cables and the amplitude of the welding current.

Fig. 2. Voltage measuring technique a) Connection to the back of the TIG torch; b) Connection to the back of the MIG gun

Care should be taken when measuring arc voltage in TIG welding as the high voltage used for starting the arc may damage the instrumentation unless it is specifically designed for arc monitoring.

Some standards now require heat input to be calculated from instantaneous values and this requires an instrument that can accurately record the waveform of the voltage and current and perform the calculation up to 5,000 times per second or more. An example of such an instrument is shown in Figure 3. Several other manufacturers provide similar instruments.

Fig. 3. AMV 4000 Data Logger – Triton Electronics Ltd

Such instruments can record and display the current and voltage waveform from pulsed TIG and MIG/MAG processes including controlled dip transfer and multi-pulse techniques.

Wire feed speed can be measured by clipping a tachometer to the wire or by attaching a sensor to the wire feed drive rolls. Temperature is measured using a thermocouple or resistance temperature detector (RTD) probe in contact with the surface or, alternatively, an infrared non-contact device. Although gas flow can be measured with a bobbin type gauge, for recording the value a mass flow type instrument is required.

Limits can be set (typically +/-10%) to indicate if the parameters have deviated outside of the procedure and statistical process control (SPC) can be used to stop or correct a process before problems occur. However, this is a relatively crude technique and TWI is investigating more advanced digital processing.

Copyright © TWI Ltd 2014

The content of this article was correct at the time of publication.