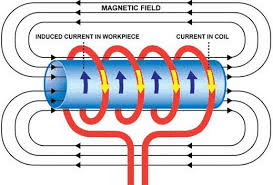

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents.

An induction heater consists of an electromagnet, and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor called eddy currents.

The eddy currents flowing through the resistance of the material heat it by Joule heating. In ferromagnetic (and ferrimagnetic) materials like iron, heat may also be generated by magnetic hysteresis losses.

The frequency of current used depends on the object size, material type, coupling (between the work coil and the object to be heated) and the penetration depth.

An important feature of the induction heating process is that the heat is generated inside the object itself, instead of by an external heat source via heat conduction. Thus objects can be heated very rapidly. In addition there need not be any external contact, which can be important where contamination is an issue.

Induction heating is used in many industrial processes, such as heat treatment in metallurgy, and to melt refractory metals which require very high temperatures.

Applications

Induction heating allows the targeted heating of an applicable item for applications including surface hardening, melting, brazing and soldering and heating to fit.

Iron and its alloys respond best to induction heating, due to their ferromagnetic nature. Eddy currents can, however, be generated in any conductor, and magnetic hysteresis can occur in any magnetic material. Induction heating has been used to heat liquid conductors (such as molten metals) and also gaseous conductors (such as a gas plasma – see Induction plasma technology).

Induction heating is often used to heat graphite crucibles (containing other materials) and is used extensively in the semiconductor industry for the heating of silicon and other semiconductors. Utility frequency (50/60 Hz) induction heating is used for many lower cost industrial applications as inverters are not required.

Furnace

An induction furnace uses induction to heat metal to its melting point. Once molten, the high-frequency magnetic field can also be used to stir the hot metal, which is useful in ensuring that alloying additions are fully mixed into the melt.

Most induction furnaces consist of a tube of water-cooled copper rings surrounding a container of refractory material. Induction furnaces are used in most modern foundries as a cleaner method of melting metals than a reverberatory furnace or a cupola.

Sizes range from a kilogram of capacity to a hundred tonnes capacity. Induction furnaces often emit a high-pitched whine or hum when they are running, depending on their operating frequency. Metals melted include iron and steel, copper, aluminium, and precious metals. Because it is a clean and non-contact process it can be used in a vacuum or inert atmosphere. Vacuum furnaces make use of induction heating for the production of specialty steels and other alloys that would oxidize if heated in the presence of air.

Welding

A similar, smaller-scale process is used for induction welding. Plastics may also be welded by induction, if they are either doped with ferromagnetic ceramics (where magnetic hysteresis of the particles provides the heat required) or by metallic particles.

Seams of tubes can be welded this way. Currents induced in a tube run along the open seam and heat the edges resulting in a temperature high enough for welding. At this point the seam edges are forced together and the seam is welded. The RF current can also be conveyed to the tube by brushes, but the result is still the same – the current flows along the open seam, heating it.

Seams of tubes can be welded this way. Currents induced in a tube run along the open seam and heat the edges resulting in a temperature high enough for welding. At this point the seam edges are forced together and the seam is welded. The RF current can also be conveyed to the tube by brushes, but the result is still the same – the current flows along the open seam, heating it.

Heat treatment

Induction heating is often used in the heat treatment of metal items. The most common applications are induction hardening of steel parts, induction soldering/brazing as a means of joining metal components and induction annealing to selectively soften an area of a steel part.

Induction heating can produce high power densities which allow short interaction times to reach the required temperature. This gives tight control of the heating pattern with the pattern following the applied magnetic field quite closely and allows reduced thermal distortion and damage.

This ability can be used in hardening to produce parts with varying properties. The most common hardening process is to produce a localised surface hardening of an area that needs wear-resistance, while retaining the toughness of the original structure as needed elsewhere. The depth of induction hardened patterns can be controlled through choice of induction-frequency, power-density and interaction time.

Limits to the flexibility of the process arise from the need to produce dedicated inductors for many applications. This is quite expensive and requires the marshalling of high current densities in small copper inductors, which can require specialized engineering and ‘copper-fitting’.

Pro Heat 35

REDUCE PRE-HEATING TIME BY UP TO 75%

Miller’s Induction Heating system brings a part to temperature in a fraction of the time, compared to traditional flame and resistance heating processes. It also holds the part at the specified temperature.

to traditional flame and resistance heating processes. It also holds the part at the specified temperature.

With Miller’s Pro-Heat, pre-heat time can be reduced by up to 75%. To put this in perspective, companies using the Pro-Heat have reduced pre-heating time from over two hours to just 30 minutes.

Multiple Outputs

Provides two insulated connectors for air-cooled blankets or liquid-cooled cables.

Low Consumable Cost

No fuel costs and minimal insulation costs. Insulation is reusable and may be used 50 times or more, reducing cost of disposal and replacement.

On-Board Temperature Control

Provides for manual or temperature-based programming in a simple-to-learn operator interface.

Multiple Control Thermocouple Inputs

Control on the hottest TC during heating and coolest TC during cooling for uniform heating and quality.

Open Output Detection

Prevents system operation without a covered output receptacle (cable or protective plug).

Air-Cooled Induction Heating System

Designed for preheating applications up to 204°C.

Liquid Cooled Induction Heating System

Designed for preheating, hydrogen bake-out and stress relieving applications up to 788°C.

Applications

Transmission Pipeline – Construction/Repair

Pipe Fabrication Shops

Power Piping – Construction/Repair

Petrochemical – Construction/Repair

Shipbuilding

Mining Equipment Maintenance

Drill Pipe Manufacturing

Shrink Fit

Easy Set-Up

Achieved using pre-heat blankets or flexible heating cables combined with user-friendly insulation blankets. Easy to install primary power through panel that does not require removal of sheet metal.

Uniform Heating

Heating is maintained along and through the heat zone by using induction to heat within the material. The surface of the part is not marred by localised conducted heat at higher than specified temperatures.

Improved and Safer Working Environments

Welders are not exposed to open flame, explosive gases and hot elements associated with fuel gas heating and resistance heating.

Cable Identification System

Knows the type of cable attached and limits output to protect cables and blankets.

Isolation Fault Protection

Provides automatic system shut down should power source output short to ground. A sense lead provides

direct feedback to the power source to sense fault condition.

Time-to-Temperature

Faster than conventional processes due to the method of applying the heat, reducing heating cycle time.

Boosts Productivity

Induction heating offers a much faster time to temperature. The part reaches the desired temperature in a significantly shorter time

compared to traditional flame and resistance heating processes, allowing the job to get done faster.

Improved Safety

Induction heating is a much safer heating process as there is no exposure to open flames or electrical resistance wires and less exposure to fumes compared to flame heating.

Reduce Costs

The faster heating time reduces costs due to less labour time, Plus there is no fuel costs or expensive ongoing inspection or audit costs associated with the Induction heating process.

On-Board Diagnostics

In-built diagnostics enables operating parameters to be available at the touch of a button and offers operator tutoring. On-board temperature control provides for manual or temperature based programming in a simple-to-learn operator interface.

Reduce Heating Time by up to 75%

With the Miller Pro-Heat, a part can be brought to temperature in a faction of the time, compared to traditional flame and resistance heating processes. It also holds the part at the specified temperature. It can be programmed to hold and soak for a specified period of time. Pre-heat time can be reduced by up to 75%. To put this in perspective, companies using the Pro-Heat have reduced pre-heating time from over two hours to just 30 minutes.